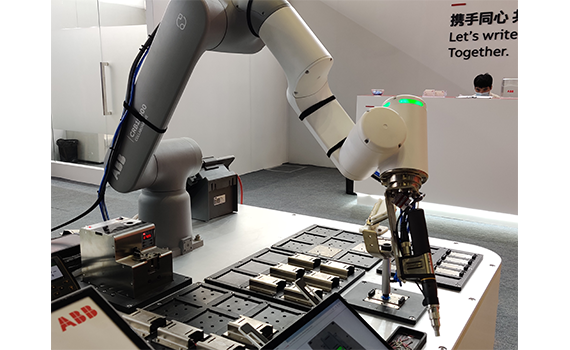

GoFa™ CRB15000 钣金组装及螺丝锁付工站

A206 | 上海ABB工程有限公司

展品介绍

该工作站演示了钣金组装的工艺流程:GoFa™ CRB15000协作机器人将钣金从来各个料盘中取出,放置到组装位进行组装,然后进行螺丝锁付。

该系统能够根据客户需求自由定制数据收集及控制界面,配合Wizard简易编程及手动拖教,可实现高效的产品切换流程以及缩短产线布置时间。

通过机器人自动化,工人得以从重复枯燥的工作中解放出来。5kg的夹具负载能使机器人可以负责更多的工作,保质保量的完成任务。

This cell demonstrates the process of sheet metal assembly and screwing. GoFa™ CRB15000 Cobot picks the sheet metals from the trays, places it onto the assembly station, then screw them.

The system could be customized according to customer requirements for data collection and control. With Wizard easy-programming software and lead-through function, it makes product changing and line setting easier.

It releases the operator from repetitive and boring tasks. 5kg payload makes Cobot could do more work.